Borescope Inspection of Gas Turbine

Gas Turbine Borescope Inspection

Importance of Borescope Inspection of Gas Turbine

BORESCOPE INSPECTION OF TURBINE

Gas Turbine Borescope Inspection

Importance of Borescope Inspection of Gas Turbine

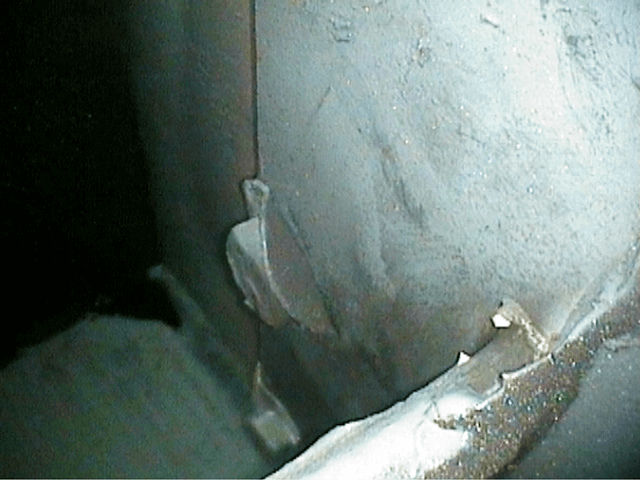

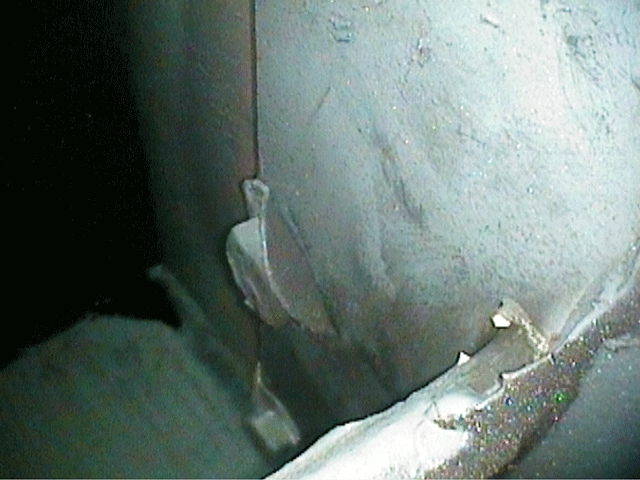

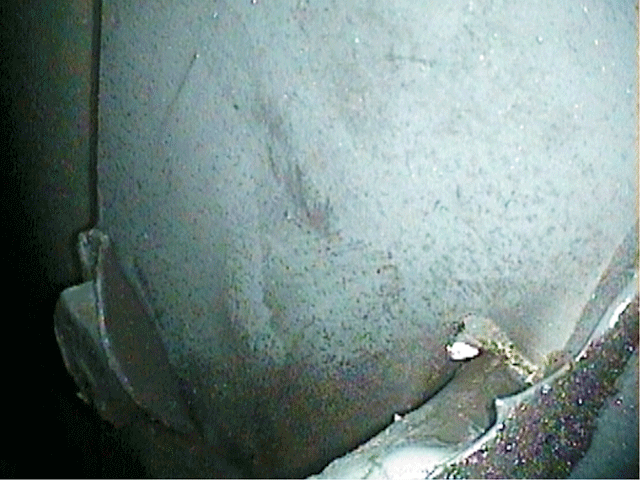

Natural gas is the second most heavily consumed energy source. Thanks to gas turbines, power plants are able to better handle this essential energy source across the world. Though gas turbines are extremely efficient, if something goes wrong, it can ruin the entire process and jeopardize the energy plant itself.

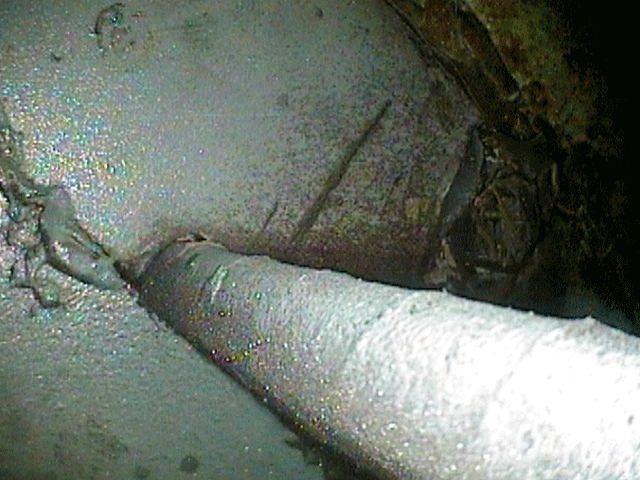

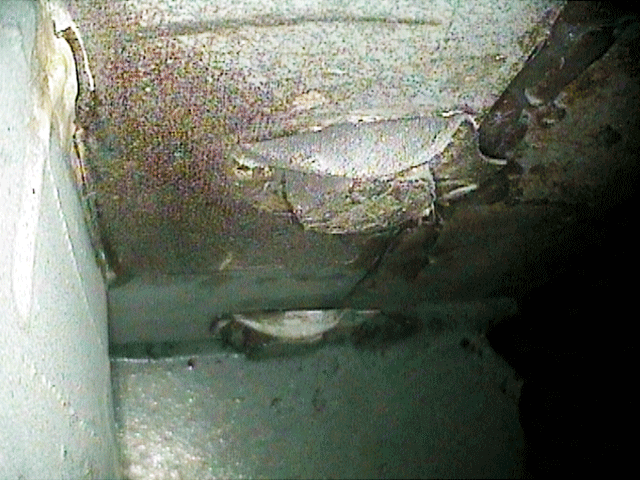

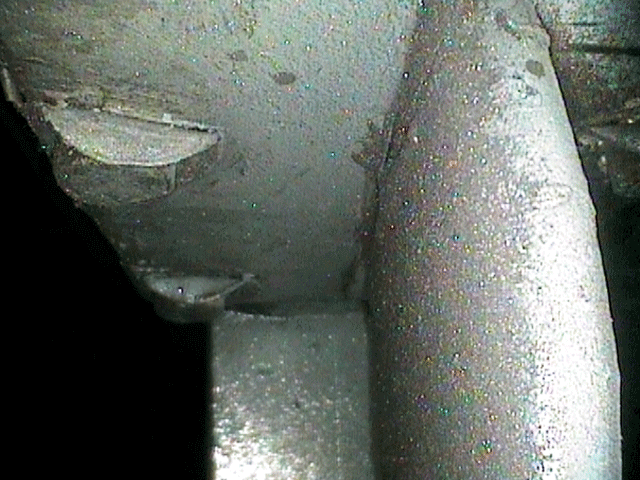

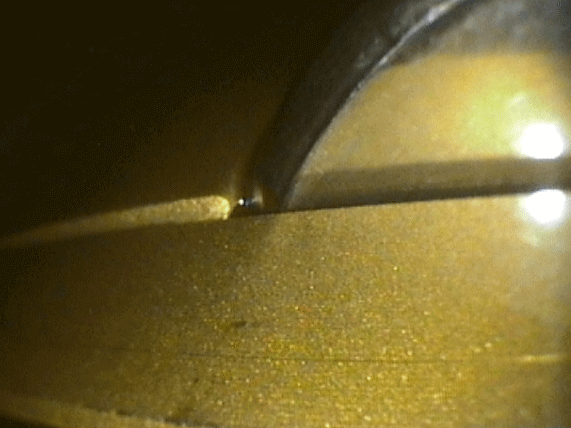

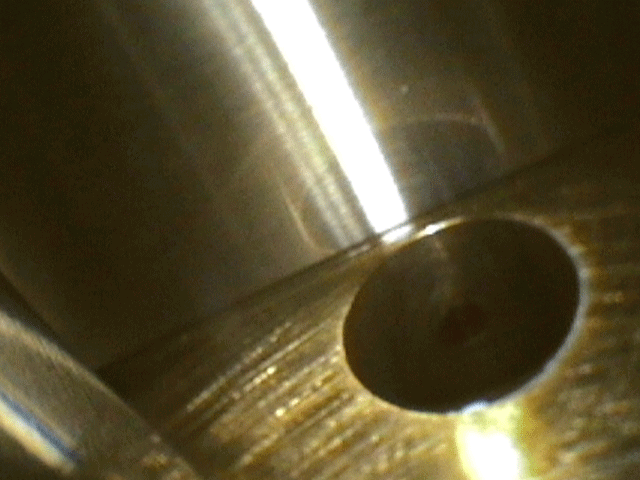

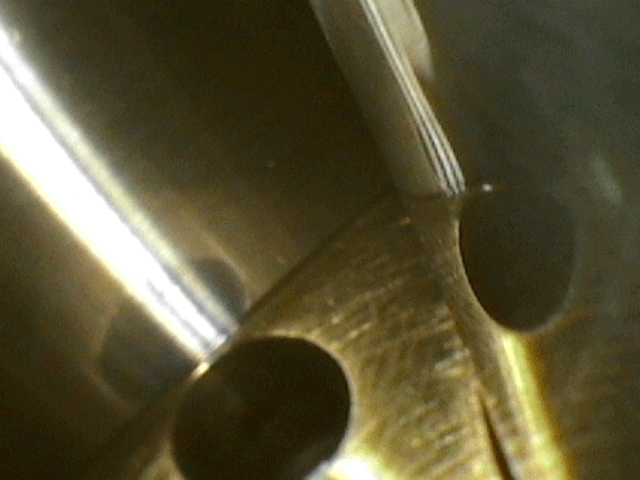

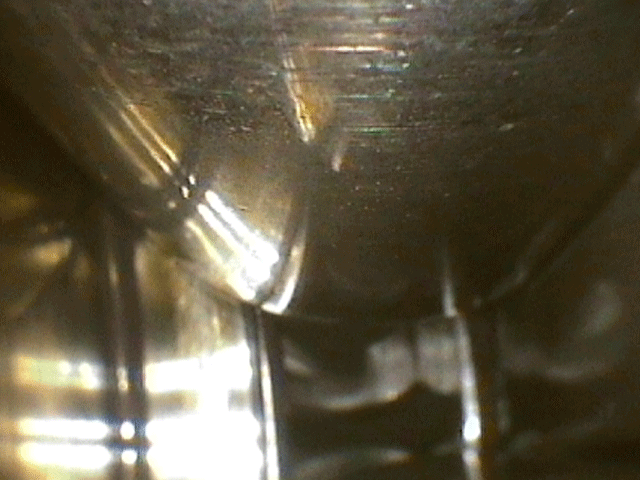

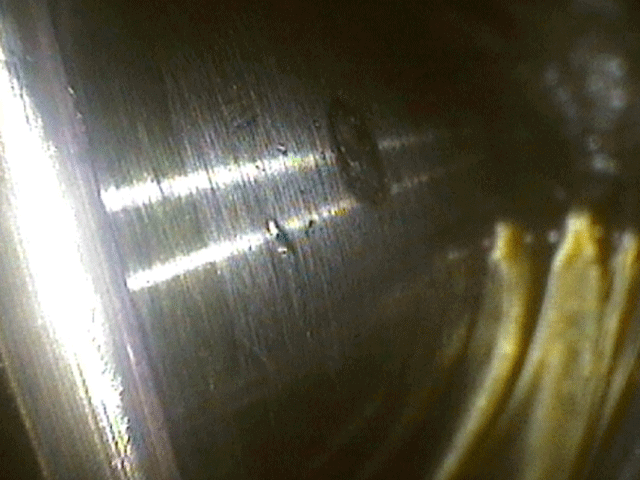

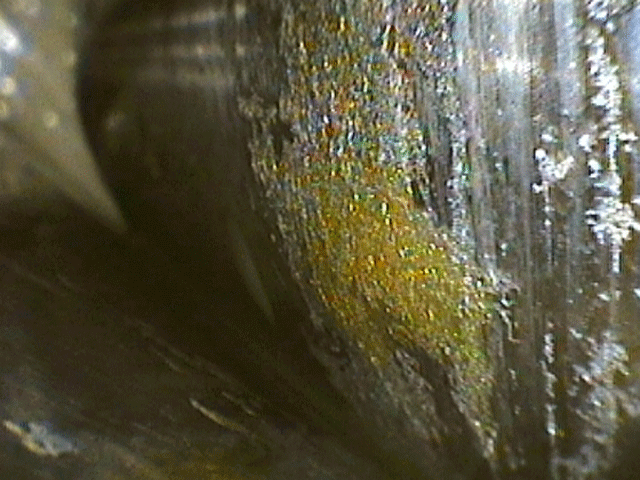

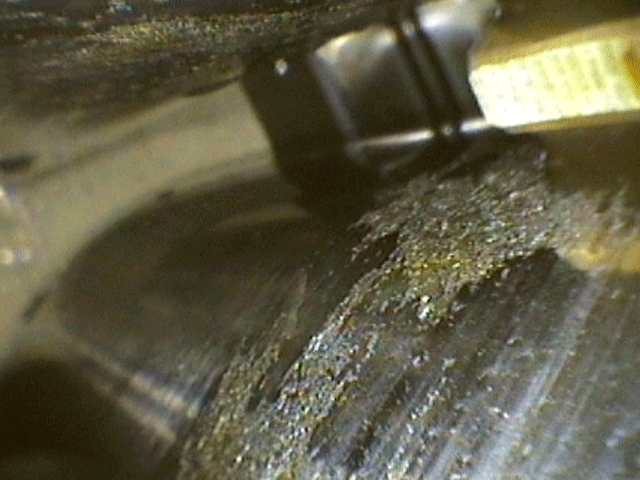

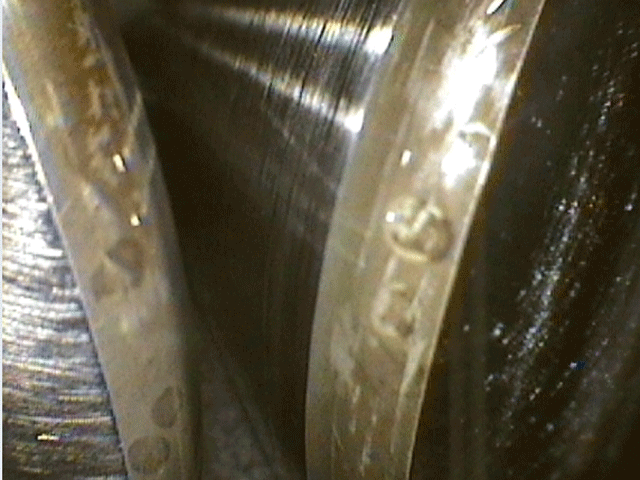

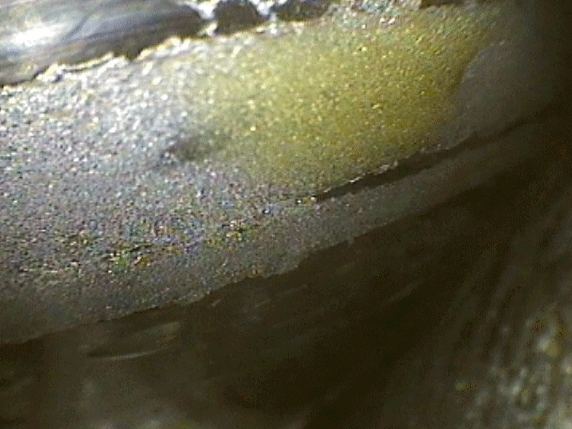

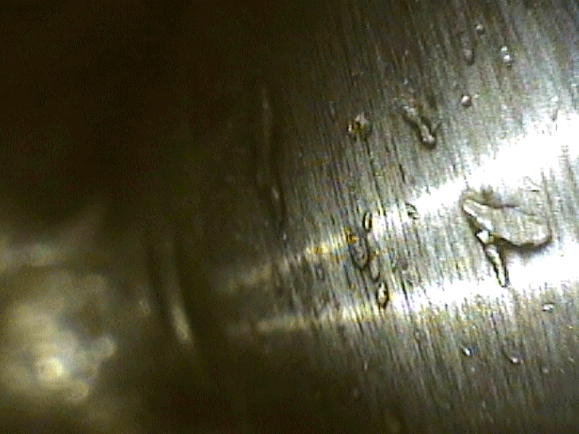

In order to keep your turbines and related equipment running properly and efficiently, you’re going to need a thorough, unbiased, NDT and RVI. Borescope inspection services can help keep your power plant equipment running as efficiently as possible.

The slightest interior defect can destroy your turbine and cause propagating damage that is extremely expensive and potentially dangerous for the employees onsite. Do not allow your operation or plant suffer from running faulty or compromised gas turbine machines. If any part of your specialized heavy equipment machines is malfunctioning, or if you need to schedule a semi-annual or annual checkup, you should contact a skilled borescope inspection team immediately.

- Pre-commissioning

- Outage planning and downtime prevention

- Baseline inspections

- Emergency issues and forced outages

- Semi-annual or annual usage

- Time sensitive assessment

- Condition based maintenance

- Post overhaul

To learn more about NDT and RVI borescope services, acquire necessary parts for your equipment to run efficiently and properly, or work with a trusted organization that can perform a thorough borescope inspection of gas turbine, contact us for details.